In recent years, 3D printing technology has gained significant momentum across the globe, revolutionizing the way products are designed and manufactured. Pakistan, with its vibrant manufacturing sector, is also exploring the immense potential of 3D printing in transforming its industrial landscape. This article delves into the potential of 3D printing in Pakistan’s manufacturing sector in 2023, discussing its advantages, applications, challenges, government support, and prospects.

Pakistan’s manufacturing sector has been a vital contributor to the country’s economy, encompassing a wide range of industries such as automotive, textile, pharmaceuticals, and more. With the advent of 3D printing, also known as additive manufacturing, Pakistan has the opportunity to unlock new possibilities and propel its manufacturing capabilities to greater heights.

Read more: 7 Best Tech Wonders You Need to See to Believe 2023

Overview of 3D printing technology

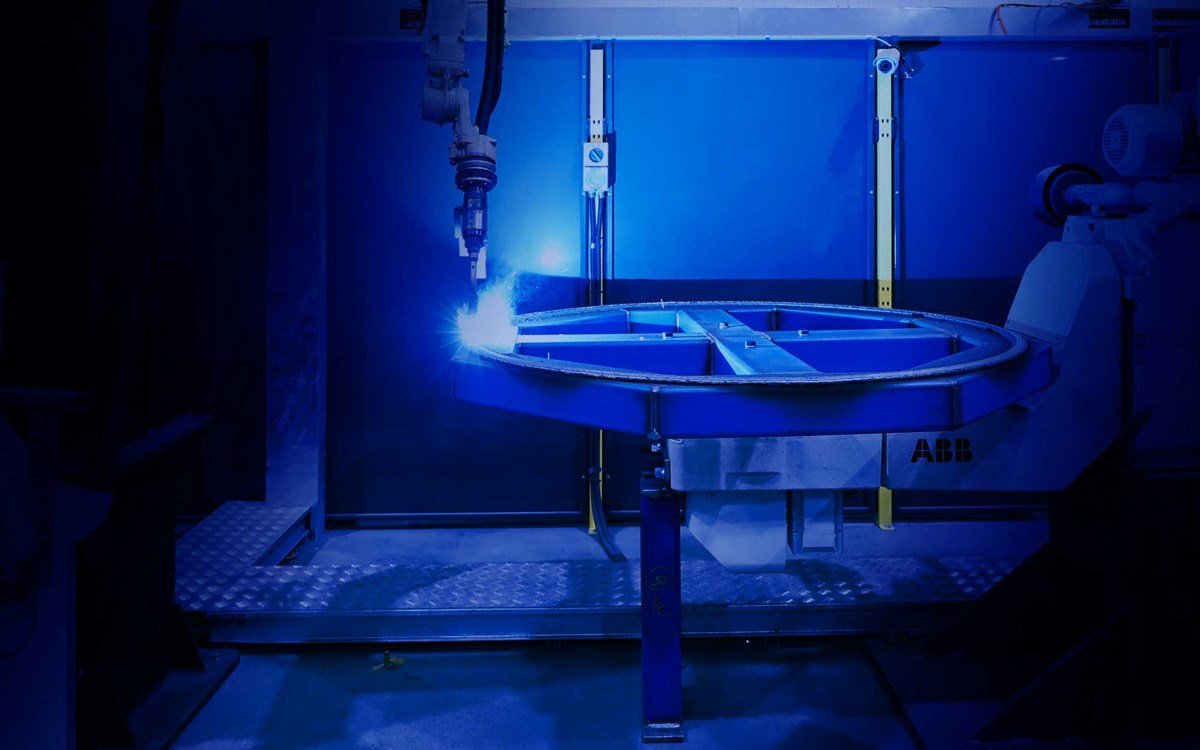

Before diving into the potential of 3D printing in Pakistan, it is essential to understand the basics of this transformative technology. 3D printing enables the creation of three-dimensional objects by layering materials based on a digital model. It eliminates the need for traditional manufacturing processes like subtractive machining and molding, allowing for greater design flexibility and intricate detailing.

The current state of Pakistan’s manufacturing sector

Pakistan’s manufacturing sector has been experiencing steady growth, contributing significantly to employment and economic development. However, it faces challenges such as limited innovation, high production costs, and reliance on imported goods. This is where 3D printing can play a crucial role in driving positive change.

The Potential of 3D Printing in Pakistan

Advantages of 3D printing in manufacturing

One of the key advantages of 3D printing is its ability to reduce costs and lead time in the manufacturing process. Traditional manufacturing methods often involve complex supply chains and high setup costs. 3D printing offers a more streamlined approach, enabling the creation of parts on demand, reducing inventory costs, and minimizing wastage.

Cost savings and reduced lead time

By leveraging 3D printing, Pakistani manufacturers can significantly reduce the lead time required to bring a product to market. Rapid prototyping and iterative design iterations become more accessible, facilitating quick product development and testing. This agility allows manufacturers to respond swiftly to changing market demands, gaining a competitive edge.

Customization and product innovation

3D printing empowers manufacturers to customize products according to individual customer preferences. This level of personalization was previously impractical or costly to achieve. With the ability to tailor products to specific requirements, Pakistani manufacturers can cater to niche markets, offering unique and differentiated offerings that resonate with consumers.

Applications of 3D Printing in Pakistan’s manufacturing sector

The potential applications of 3D printing in Pakistan’s manufacturing sector are vast and diverse. Here are some notable areas where 3D printing is making an impact:

Automotive industry

The automotive industry in Pakistan stands to benefit from 3D printing technology. Components such as engine parts, customized interior features, and even entire vehicle prototypes can be manufactured using 3D printers. This opens up avenues for cost-effective production, reduced reliance on imports, and increased innovation in the sector.

Healthcare sector

In the healthcare sector, 3D printing has the potential to revolutionize patient care. Customized medical implants, prosthetics, and surgical models can be tailored to individual patients, resulting in improved treatment outcomes. Additionally, the production of pharmaceuticals through 3D printing holds promise for personalized medicine, allowing for precise dosage and drug combinations.

Consumer goods

The consumer goods industry can leverage 3D printing to manufacture customized products, such as personalized jewelry, home decor items, and fashion accessories. This enables Pakistani manufacturers to tap into the growing demand for unique and personalized goods while reducing production costs and inventory requirements.

Architecture and construction

In the field of architecture and construction, 3D printing offers exciting possibilities. Large-scale 3D printers can create intricate building components, reducing construction time and costs. This technology allows for the construction of sustainable and energy-efficient structures, addressing the challenges faced by the construction industry in Pakistan.

Challenges and Limitations of 3D Printing in Pakistan

While the potential of 3D printing in Pakistan’s manufacturing sector is vast, several challenges and limitations need to be addressed. These include the high upfront costs of 3D printers, limited access to skilled professionals, and the need for robust quality control measures. Overcoming these obstacles requires collaboration between industry stakeholders, government support, and investments in research and development.

Government initiatives and support for 3D printing

Recognizing the transformative potential of 3D printing, the Pakistani government has taken steps to promote its adoption in the manufacturing sector. Initiatives such as research grants, tax incentives, and partnerships with educational institutions have been introduced to foster innovation and skill development in 3D printing. These efforts aim to position Pakistan as a hub for advanced manufacturing in the region.

Prospects and Growth of 3D Printing in Pakistan

Looking ahead, the prospects of 3D printing in Pakistan’s manufacturing sector appear promising. As technology advances and becomes more accessible, the adoption of 3D printing is expected to accelerate. Pakistani manufacturers can embrace this technology to enhance their competitiveness, drive innovation, and tap into new markets both domestically and internationally.

Read more: The Challenges of Building a Tech Start-Up in Pakistan in 2023

Conclusion

The potential of 3D printing in Pakistan’s manufacturing sector in 2023 is immense. By embracing this transformative technology, Pakistani manufacturers can unlock cost savings, reduce lead time, customize products, and drive innovation. However, overcoming challenges and ensuring adequate government support and investments are crucial for realizing this potential. With the right approach and collaboration, 3D printing can shape the future of Pakistan’s manufacturing industry.

FAQs

Is 3D printing widely adopted in Pakistan’s manufacturing sector?

Currently, 3D printing is still in its early stages of adoption in Pakistan’s manufacturing sector. However, the technology is gaining traction, and several industries are exploring its potential.

How can 3D printing benefit the automotive industry in Pakistan?

3D printing can benefit the automotive industry in Pakistan by enabling the cost-effective production of customized components, reducing reliance on imports, and promoting innovation in design and manufacturing.

Are there any limitations to 3D printing in Pakistan?

Yes, there are some limitations to 3D printing in Pakistan, including high upfront costs, limited access to skilled professionals, and the need for quality control measures.

What government initiatives support the growth of 3D printing in Pakistan?

The Pakistani government has introduced various initiatives such as research grants, tax incentives, and partnerships with educational institutions to promote the adoption of 3D printing in the manufacturing sector.

What does the future hold for 3D printing in Pakistan?

The prospects of 3D printing in Pakistan’s manufacturing sector are promising. As technology advances and becomes more accessible, the adoption of 3D printing is expected to accelerate, driving innovation and growth in the industry.